What is a Tech Pack?

Time to read: 16 minutes

You will have heard of the term tech pack before as you are on this website! If you’re not sure what exactly that entails, read on for the full explanation here.... We will cover what a tech pack is, isn’t, how it works and how you can make one.

What is a tech pack?

A tech pack is a document with images, text and numbers that explains your product design. Fashion designers use these to show to a factory how they want their product to look and how they want their product made. There are many sections you can include in a tech pack, we will get into those later. For now, know that the goal of your tech pack... is to be the 1 reference for your product designs - for both you the designer and your factory.

“A tech pack is a digital communication tool between a maker and their factory. The goal of a tech pack is to have a single document where ALL relevant, materials, specifications and drawings... can be found. ”

As anyone in the industry will tell you, designing a product for manufacture, from scratch is no easy feat. It’s usually not a simple 1, 2, 3 step process… it’s much more involved than that. The tech pack is a simple and clear way to organize your product design information throughout the manufacturing process!

Tech packs & common misconceptions

There are many misconceptions when it comes to tech packs. As there is no official industry standard method for tech packs! The format & structure changes depending on the company, country and type of product. Here are a couple of things that are often confused with tech packs:

Patterns

A pattern is the actual template of your design and is usually made up of many pieces. On a t-shirt for example... you would have a pattern piece for the t-shirt front, one for the t-shirt back and another for the sleeves. The pattern is drawn, then placed on top of your fabric. A cutter (can be a machine or person) will use the pattern as a template to cut out the fabric. You then have correctly shaped pieces of fabric ready to be sewn together. Patterns can be drawn by hand onto paper, or drawn digitally using software.

Digital Patterns. Image via https://optitex.com

Paper patterns. Image via http://insider.utelier.com

Purchase orders

A PO form is used for ordering bulk production from your factory. This form breaks down your desired quantities by style, size and color variants. You would also include terms, due dates, freight and delivery information here. Only when you are ready to proceed with your bulk production would you send your factory a purchase order.

READ MORE → Tech Packs, Patterns & Spec Sheets

What a tech pack means for your business

The benefits of having a tech pack make the investment a no brainer. Here are the top 6 reasons you’ll be better off after you’ve got your tech pack:

1. Get accurate prices from suppliers

If a factory can see exactly what’s in your product when they quote you, you can hope to get an accurate price. If they are guessing about the details of your product, you can only receive a guesstimate! If you are looking for a new supplier... Speak to a few sewing contractors and compare prices, timelines and workmanship. Getting the right quality product at the right price is what this business is all about.

2. Speed to market

Want to spend 6 months developing your new style? With several rounds of samples, lengthy meetings and long email chains? That’s a resounding no! With a tech pack... you should be able to approve samples without a long & expensive development process. Get that new product to market quickly and start profiting sooner.

3. Quality Control

Use the specifications from the tech pack to keep your factory and your own team on track. Things change over time, employees can leave and materials can go out of stock. Ensure your product stays consistent no matter what. Keeping the product specifications up to your standards will reduce return rates. It will improve customer satisfaction and create brand loyalty. Cue singing angels.

4. Headache and fuss free

If you’re not a fan of disappointing results, missed deadlines and emergencies... a tech pack is for you. Manufacturing is expensive and complex, so why not make the process as simple as you can. Communicate clearly to your factory and reap the benefits of your efficiency. If you’re easy to work with, you won’t be last priority if your factory has any shortages or when they’re running late.

Imaging trying to assemble some furniture from ikea without the little instruction booklet they give you. It would take 10x longer and wouldn’t any be looking any better for it!

READ MORE → Tech Packs: What’s the Big Deal

How to create a tech pack?

Before you begin, you’ll need three things:

1. Your Design

What does your garment or product look like and what is its purpose? You’ll need some kind of imagery or rough drawings and notes, before you start. Just enough to show what the design will look like and include.

2. Your fabric

The type of fabric you want to use will have a huge effect on what your product will look, feel and wear like. This decision should be made before you've even fully designed your product! The fabric you use has to be suitable for your product design otherwise it won’t work or look appealing.

3. Your prototype or fit sample

This is a physical item representing the size and shape of your product. Your sample can be custom made by a professional, by a tailor or DIYed by yourself. Buying an existing product from a shop and getting creative with a stapler, tape, scissors or pen works too!

This piece is crucial to starting off your tech packs on the right foot. Creating measurements pulled from your head in a tech pack is a recipe for a LONG development process. You’ll get to that perfected sample stage much quicker when you start off with approximate dimensions that you already know are correct and fitted the way want.

After this, you can start putting your tech pack together. There are two main stages to this:

1. Drawings

First, you’ll need to create a professional drawing of your design. This needs to be a technical drawing, which is known in the fashion industry as a flat sketch. This is a black/white line drawing, that shows your sketch as if your product is laid flat on a surface.

“A picture is worth a thousand words. #techpacksecrets”

No fashion illustrations needed here. A clear drawing that shows to-scale, exactly how your style looks. Leave out color, shading, and styling for now! The most widely used program for this is Adobe Illustrator, but any vector software or black fine-line pen will work

2. Text

After you’ve got a complete drawing you can start putting your tech pack together. The job title for this in industry, is called a technical designer, or a garment technologist in the UK. Bigger firms use PLM software for creating and managing hundreds and thousands of tech packs in one go.

Small brands and independent designers often use good old Microsoft Excel. If you don’t have a 5 figure software budget, I would also recommend using Excel. The formula functions are useful for when it’s time to write your measurement page. If you know how, you can set up a tech pack simply and quickly using multiple sheets in one workbook. If this is you, check out our time saving templates in the shop.

Lastly, I would recommend exporting the final excel workbook, including your sketches, as a PDF file. If the file is over 2MB I would recommend compressing the file size down, before you send it to a factory.

READ MORE → The Best Apps, Tools & Hacks for your Tech Packs

What exactly is included in a tech pack?

Let’s detail all the sections that will go inside a professional tech pack. If you can layout each of these sections on a new page, it helps to keep things clear and easy to read.

Bill of materials

Just as it sounds, this is a list of all your materials and components. Details can be broken down into; name, placement, composition, color, quantity and supplier. Don’t forget to include photos and drawings to show what things need to look like. When talking fabrics, it’s also important to note weights or thicknesses. Fabric width is also useful if you know it. Check out our example below.

Callouts

These are bullet descriptions written alongside your image. Keep sentences short and easy to read (it’s easier to translate). Don’t forget that the people making your products may not be English speakers. (Even if your product is made in the US or UK)! Be descriptive and specific here. Don’t leave any information out, even if it seems self explanatory.

Construction

This section details the sewing and assembly of your design. ISO stitches are included, as well as the seam type, width, allowance and stitches per inch for each operation.

Colorways

Of course you will need to show all the colorways your design will be available in. Remember to include PANTONE references if you are having fabrics and trims dyed to match.

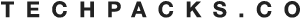

Artwork

Here is where you can detail any textile repeat prints, any graphics or logos. Don’t forget to specify dimensions and placements. There any many printing effects and types of ink too. It’s a good idea to detail any other decorative elements here as well, you can always add more pages too.

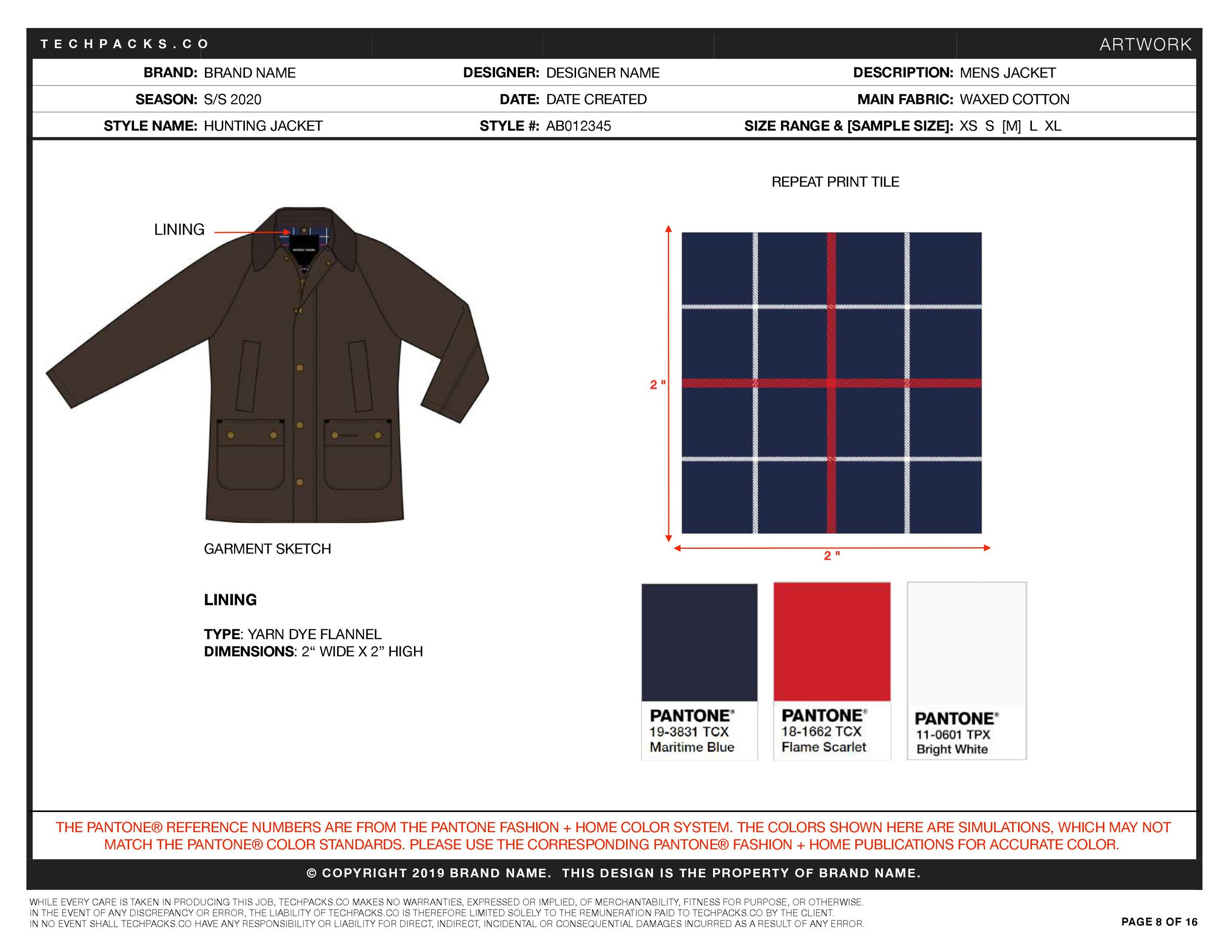

Labels

You’ll probably want two different labels if you are designing a piece of clothing. Brand labels (with your branding on), go in the back neck of tops, or the back waistband of bottoms. You’ll also need to include a care label. This label is normally found down the side of your clothing. It details care instructions, fabric composition and country of origin.

Packaging

We recommend having your products folded and sealed into a basic polybag for protection in transit. This works best for most apparel products. If you have more complex packaging needs they can be outlined here instead.

Measurement Spec

The meat of the tech pack - your product measurements! Each measurement comes with a detailed description, as well as a level of manufacturing tolerance. If your design comes in multiple sizes, each size will need it’s own set of measurements.

POM Diagram

This is a simple diagram with arrows and labels, showing which measurement from the page before is measured where. As mentioned in the drawing section of the article, your sketch should be drawn to scale. This ensures your arrows will be accurately showing where each measurement is placed!

How to use your tech pack

Now you know how to begin and complete a tech pack… you’re probably wondering exactly what you can do with your tech pack. Here is a quick overview of the next steps.

Step 1: Sourcing

Use your tech pack when you contact new suppliers. Along with a breakdown of your order quantities (by style, size and color). A factory should be able to give you a reasonably accurate quote.

Step 2: Sampling

If this sample is the first, 3D, in-real-life version of your design… you may want to make some tweaks. You are fairly likely to want to develop your design once you get your first sample back. Invest the time to get your sample right. You want to make this the best design it can be! It’s going to be too late to change anything once you move to the production stage, so now is the time to test, adjust and test again. Use your tech pack to document any updates as you go.

Step 3: Production

When you ready to start actually mass manufacturing, keep your tech pack to hand. Have a few samples pulled from the production line for quality control. Make sure to check these against your tech pack. If you are lucky enough to keep repeat ordering the same style… again, remember to keep using the tech pack for quality assurance. As more time passes, it becomes easier for things to slip through the cracks!

Thank you for staying to the end of our tech pack 101! If you’re ready to start simplifying your production and speeding up development... book a no obligation free consultation with us here.

Author Bio

Tech Packs Co founder Belinda is a technical fashion designer from London, now based in Los Angeles. Belinda had her first job in fashion at the age of 15, fixing swatch cards together. Since then, Belinda has been designing & creating tech packs for more than a decade... for household name brands and independent designers alike.