What Is a Tech Pack Made of? All You Need to Know (Free Tech Pack Example Inside)

Michael Burrows, Pexels

In your day-to-day work as a fashion designer, you may sketch with pens and watercolors, or sew and drape fabrics. Regardless of what you’re creating, at some point, you will need to get into the specifics of your garment design in order to translate your vision into a blueprint and communicate it to your team and manufacturers. The best way to accomplish this is with a good tech pack.

"What is a tech pack?" or "How to make a tech pack?", you may ask. Or what about how to protect a product design from copyright infringement? Well, you’re in the right place to find out! This article will clear up any confusion and reveal some trade secrets you might not have learned in fashion school.

What is a Tech Pack and Why Do You Need It?

cottonbro, Pexels

The road to completing a fashion line is full of challenges. Miscommunications between designers and factories are possible, as are mistakes and inaccurate samples. A production delay is not only frustrating but also expensive. That is why a tech pack has become the industry standard for producing any piece of clothing. It is used by fashion designers everywhere, and it has even spread to other industries.

Before we see the components and look at a tech pack example, let’s start with the basics: what is a tech pack?

A tech pack is the technical documentation created for clothing or textile products, usually by a technical designer. It contains flat sketches, material specifications, dimensions, instructions, and everything else the factory needs to create your product accurately. Sometimes, a tech pack gets confused with a garment spec sheet or a pattern.

Top Benefits of Using Tech Packs

Ivan Samkov, Pexels

A tech pack is essentially an instruction manual for your clothing factory. Here are some of the primary benefits of investing in one:

1. Envision Your Design to the Last Detail

A tech pack allows you to ponder on all the details of your garment and identify issues that you might not have noticed simply by looking at your hand-drawn fashion sketches and storyboard.

From a business standpoint, you wouldn’t want to dive headfirst into production. Too much can go wrong without adequate instructions. That is why it is best to create a professional and detailed tech pack to be confident that your dream design is possible and practical.

Furthermore, as you gain more experience, you can refer back to your older tech packs to see how you solved a specific problem. For example, you can look through an old T-shirt tech pack to see which fabric supplier you used in the past and if you were happy with the quality, use it again.

So, while it may appear to be an extra expense at first, you will thank yourself later for doing it.

2. Cut Production Costs while Increasing Efficiency

The value of the apparel market is expected to reach almost $2 trillion by 2026. Quality control is critical if you want to reap the benefits of your industry, and tech packs are an essential step towards it.

Less confusion and back-and-forth in production will help you come up with ‘the golden sample’ and fulfill your design vision much faster and with lower production costs. Get to market before your competitors do.

Additionally, providing your factory with the exact specifications from the start will allow them to make an accurate price estimate for your product, which is a win-win situation for everyone involved.

3. Improve Communication with the Manufacturer

Some may argue that sending a sample to the manufacturer and instructing them to replicate it is enough. It’s not that simple — many things can go wrong with this approach:

One sample is not enough for everyone at the factory to review your design;

The sample may get lost or damaged along the way;

They can’t know all the details that go into the garment, nor the exact measurements or preferences;

This sample won’t reflect any improvements, updates, or changes made along the way;

You’ll have nothing to show your QC team;

You’ll have no internal record for your own team.

Better communication leads to a better relationship and a fruitful long-term collaboration. Suppliers have to juggle many projects and clients at varying levels throughout the year. Become their best and easiest customer by being clear, responsive, organized, and easy to work with.

4. Fulfill Your Social and Environmental Responsibilities

Consumers around the world are becoming increasingly concerned with how their clothes are made, who makes them, under what conditions, and what carbon footprint they leave.

Tech packs reduce trial and error in production, resulting in less energy and water use, fewer chemicals, and, above all, fewer fabrics ending up in landfills.

What about the people who sew your clothes? If you value their labor, you wouldn’t have them recreate something from scratch when a mistake could have been avoided from the start.

Therefore, not only will tech packs help you become more organized and efficient as a fashion designer, but you will also be living proof that we can improve the fashion industry on multiple levels.

5. Protect your Product Design: A Few Words on Fashion Intellectual Property (IP)

Gustavo Fring, Pexels

A somewhat complicated legal aspect (as most legal issues are), that is essential to comprehend as a designer, is how to protect a product design from copyright infringement.

If you plan on manufacturing your new fashion collection overseas, beware of accidentally handing over the intellectual property (IP) of your designs.

This usually happens if you don’t do your own development work, meaning you have a design idea but don’t check its feasibility by creating a detailed tech pack. Instead, you rely on the manufacturer to do the technical documentation and designs for you or use their stock designs. Oftentimes, they offer this service for free if the designer or fashion company commits to buying the end product from them.

What appears to be a good deal in the moment can cause a lot of trouble later on by (unintentionally) granting them ownership of your intellectual property. After all, they did all the work to bring your idea into existence and, according to law, “copyright does not protect ideas, concepts, systems, or methods of doing something”.

This isn’t to say that foreign manufacturers can’t wait to steal from you, but it’s bad practice not to fulfill the bare minimum requirements to protect your IP. If they want to take advantage, they can easily do so, and you would have no legal grounds to sue. It’s unlikely you’ll be able to apply for your own copyrights, trademarks or patents for designs that are somebody else's creation.

In addition to delivering a comprehensive tech pack, there are a few more legal aspects to keep in mind. If you want to prevent your product from appearing in stores under a different brand, you need to create these legally-binding contracts:

Product Development Agreement — this is meant to protect your molds/tooling so that the factory only uses them for your products;

Manufacturing Contracts (OEM, CM, and ODM) — all about deadlines, clauses, ownership, responsibilities, and more. It’s important to have the contracts written in the manufacturer’s native language so that the terms of agreement are as clear as possible;

China NNN Agreement — non-disclosure, non-use, non-circumvention agreement. You need this if you work with Chinese manufacturers.

What Is a Tech Pack Made Of?

You’d be surprised to learn that this essential procedure is not officially regulated. There’s no official industry standard. However, if you follow the best practices outlined in this article, your tech packs will be well received and easily understood by any factory in the world.

First of all, before diving deep into making a factory-ready tech pack, you need to have your technical drawings ready (your flat sketches or flats). The tech pack software we recommend is Adobe Illustrator.

Second, you must be familiar with Microsoft Excel, Google Sheets, or other spreadsheet or layout software in order to create the content for the tech pack.

Without further ado, here are the essentials of how to make a tech pack, accompanied by a couple of snapshots from the tech pack example we have put together for you:

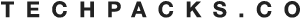

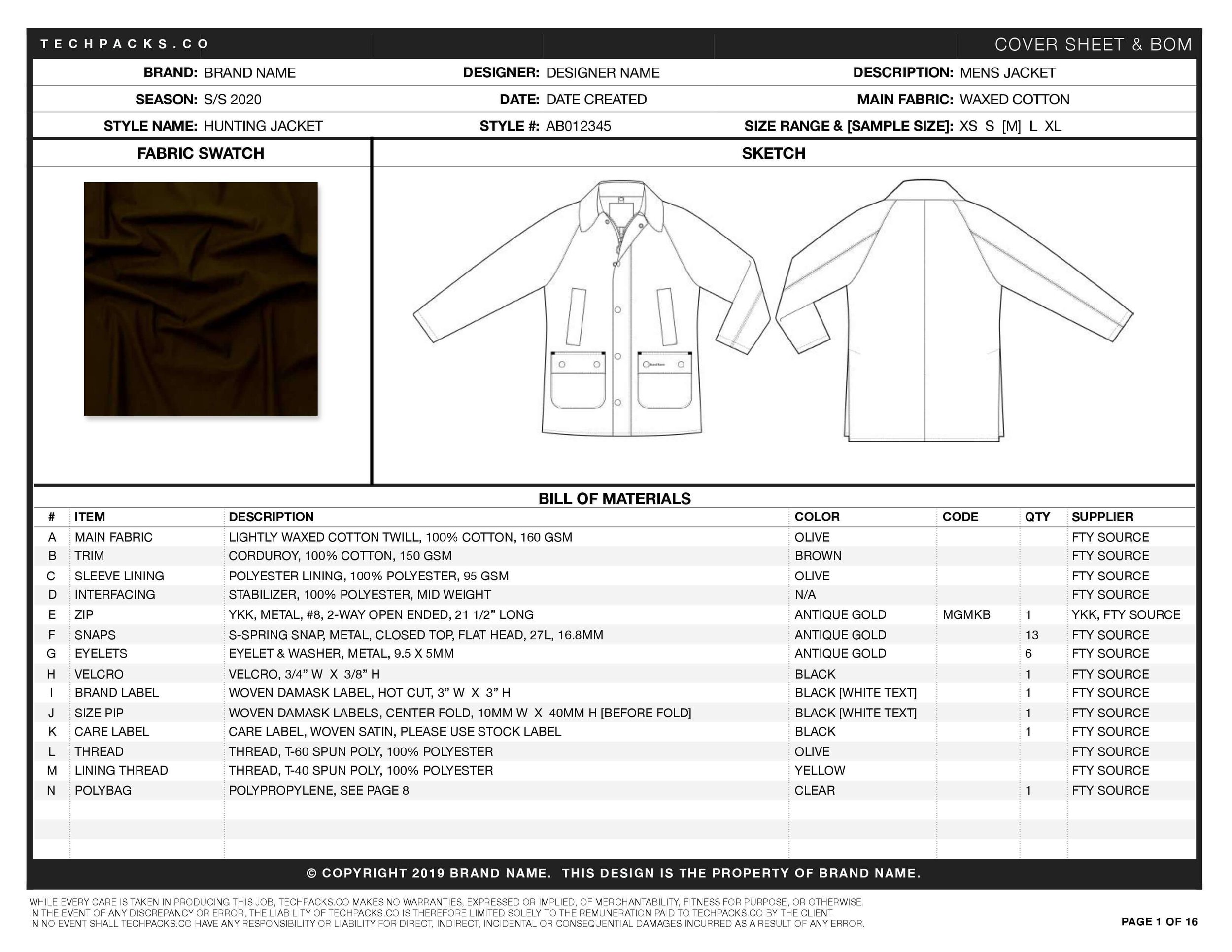

1. Lead Sheet, Description Sheet, or Cover Sheet

This includes the front, back, and if it’s a complex design, the side view of the garment. You can also include introductory information like style names, style numbers, date created/updated, and designer name.

2. The Bill of Materials (BOM)

cottonbro, Pexels

This section catalogs all the materials, their descriptions, placement, quantities, and the supplier name. Materials also include the trims, threads, buttons, and other elements that are added to your product.

Make sure to also specify any spare buttons that will be attached to the finished garments, as well as items that go on the inside of the product, on the back or between other layers.

The BOM should also offer information regarding the fiber content (the percentage of each fiber in the fabric), the structure of the material, the weight (GSM), as well as the sourcing. Include pictures of materials, trims and fastenings for each component that makes up the garment.

3. Measurement Specification Sheet

Anete Lusina, Pexels

The garment specification sheet is where you indicate how you’ve measured the distances on the garment. For a button down shirt tech pack, for example, you measure everything on it: the collar circumference, the length and circumference of the sleeves, and so on.

You’ll also need to draw a visual representation of the measurement points. Add arrows to your technical drawing to illustrate which measurement goes where.

Make sure to provide measurements for all the other sizes that your garment is available in, not just the sample size (which is the middle size of your range). Specifying the measurement difference between each size is called a grade rule. A T-shirt, for example, can vary by 4′′ in the waist from a small to medium size.

If you want to learn how to complete the grading yourself, check out this reference book — but be warned that it is a complex process, best completed by an experienced professional. . If you’re new to the topic of grading, this demo shows you a professional pattern cutter doing this using software.

While some of these sections can be omitted, garment spec sheets, grade rules, and measurement diagrams should be included in any tech pack, regardless of complexity.

4. Callouts

This includes your fashion flats with text callouts indicating the placement of various elements such as design details, hem vents, or sleeve cuts.

5. Construction Details Sheet

This is where you detail all the seams, joins, and gussets of your design, front and back. All seams need stitching or adhesive information, along with information on widths, stitches per inch, plus stitch and thread type/color.

As always, providing diagrams here to show this information instead of telling is the way to go. We recommend visuals showing the seam formation as well as a picture of the stitch type.

6. Colorways

Kaboompics, Pexels

In this sheet, you group the materials from your BOM by color. If your T-shirts come in black and white, you must specify in your T-shirt tech pack which thread or embroidery color goes with which shirt color.

Pro-tip: Offer multiple colorways so that consumers can find the most flattering option for them if your costing and product assortment can handle additional SKUs. Also, pay attention to details and provide all the information; otherwise, your factory may make decisions for you that you don’t agree with. Provide the correct Pantone references for each color item appearing on your product.

7. Artwork

If applicable, include information about the fabric prints you want to use, specifically what type of printing or other surface decoration technique you have planned. Don’t forget to add dimensions for your artwork and placement instructions too.

8. Labels

Add digital sketches of your garment that include each label, its placement, and dimensions. Labels can include things like brand labels, which have your branding and logo on. They could also include things like paper hang tags or additional tear-away labels. Remember to include a care label on your garment or textile accessory too. Compliance requirements usually include your brand/company name, country of origin, fiber composition, and washing instructions.

9. Folding and Packaging

In this section, add written instructions for the folding technique of the garment, accompanied by diagrams to show the process. Include the estimated measurements after folding, as well as the type of packaging in which the garment will be placed.

The packaging sheet should include details such as brand name placement, material, colors, bag and logo sizes, and diagrams.

We often use polybags for our tech packs, but we can add cardboard packaging details, too.

Once you have your tech pack, you can use it to:

Find manufacturers and request price quotes;

Use it in pre-production to request and approve sample garments;

Refer to the tech pack in the production stage to recreate the garment;

Keep the tech pack on hand in the future for QC purposes.

Need a Helping Hand with Your Tech Pack? We Are Here for You!

cottonbro, Pexels

It’s safe to say that tech packs are vital in fashion design because they enable seamless production from start to finish, while also responding to an increasing need to work more sustainably.

Have a look at our services if you need assistance in creating your own tech pack for future collections. We work with both independent fashion designers and brands from all over the world, manufacturing clothing and other soft goods.

Get in touch today for a free consultation to see how we can collaborate to get you a factory-ready tech pack in no time!

Author Bio

Tech Packs Co founder Belinda is a technical fashion designer from London, now based in Los Angeles. Belinda had her first job in fashion at the age of 15, fixing swatch cards together. Since then, Belinda has been designing & creating tech packs for more than a decade... for household name brands and independent designers alike.