Why Factories Aren’t Replying to Your Emails (and What to Do About It)

Time to read: 7.5 minutes

If you’ve ever sent dozens of inquiry emails to factories and heard nothing back, you’re not alone. Many new fashion brands face the same silence when they first start reaching out to manufacturers. But here’s the truth: factories aren’t ignoring you out of spite. They’re filtering fast.

Understanding why factories don’t reply to emails is the first step to getting noticed and building real supplier relationships. Let’s unpack what’s really going on behind that inbox silence—and how to fix it.

1. Your Email Makes you Look Like a Time Waster

Factories get many inquiries every week, often from people who aren’t ready to order or don’t yet have their designs figured out. If your email sounds vague, like “I want to start a clothing line; can you make my designs? ”—it’s likely being skipped. Factories are in the business of mass production, so if your email makes no mention of a bulk order, that may be a warning flag for them.

What to do instead: Be clear and specific. Include the type of product, materials, quantity, and timeline. A concise, professional email shows you’re serious.

✅ Example: “I’m developing a line of women’s activewear using nylon/spandex blends. Our first production run will be 500 units per style. Could you share your MOQ and sample timeline? ”

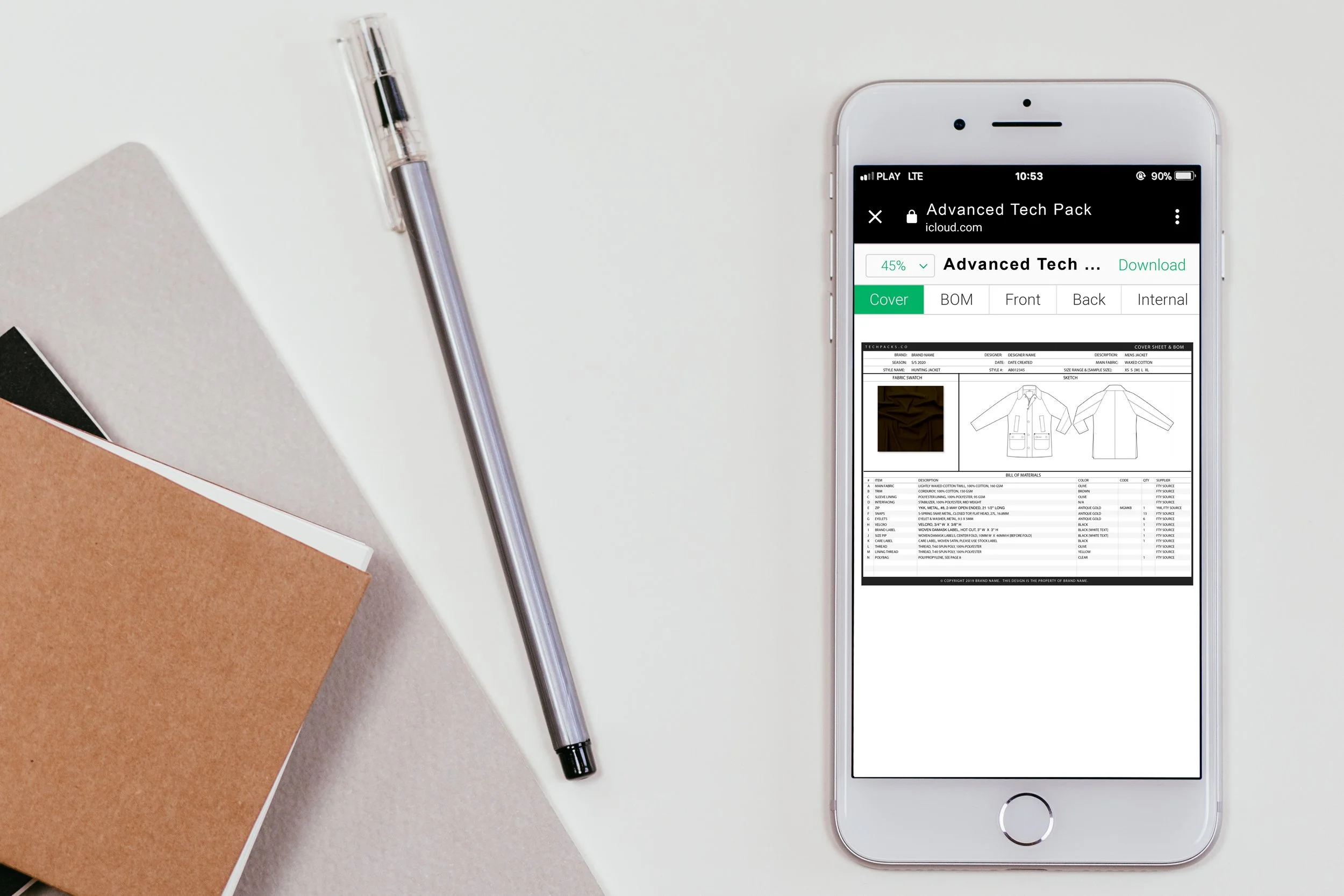

2. You Don’t Have a Tech Pack

Without a tech pack—the blueprint that shows exactly how a garment should be made—a factory can’t give you accurate pricing or production details. No tech pack = no quote = no reply.

Factories prefer working with brands that know what they want. A clear tech pack tells them you’ve done your homework and are close to being ready for a production run.

Fix:

Create a professional tech pack with garment specs, measurements, materials, trims, and reference photos. This one document can make the difference between getting ignored or getting a quote.

3. You’re not asking for quotes.

Before starting the development process with a factory, it’s best to ask for quotes. You’ll be letting them know exactly what you want to produce and how much. Now is the time to ask for a price on that specific order.

Factories will want your verbal agreement on your unit cost, ok, before they start making samples for you. Making samples for you is not a profitable process for a factory; they’re helping you out so that you can feel ready to place that bulk order.

Sometimes costs change as your sample develops, but it’s that initial alignment that benefits both the brand and the factory—when no one is surprised later on.

4. Your Quantities Are Too Low

Factories operate on tight margins and plan their production calendars months in advance. If you ask for 100 pieces when their minimum order quantity (MOQ) is 1000, they simply won’t have the time to respond.

Fix:

Start with sample development or work with low-MOQ manufacturers who specialize in small-batch production for startups. You can also test your product with pre-orders before scaling.

5. Your Message Isn’t Reaching the Right Person

Sometimes, your message does get sent but lands in the wrong inbox. Contact forms or generic email addresses like info@factoryname.com can get lost in a sea of spam.

Fix:

Find the right contact person, ideally a production manager, business development rep, or sample room coordinator.

You can often find these contacts via LinkedIn or the factory’s website. A direct message to the right person increases your odds of getting a reply.

6. You’re Not Building a Relationship—You’re Making a Demand

Factories want long-term clients, not one-off orders. If your tone feels transactional—“How much for this? “You’re missing the opportunity to build rapport.

Fix:

Show genuine interest in their capabilities and learn what a “good” order looks like for them. Ask questions like

“What types of products do you specialize in? ”

What are your capabilities for XX (insert a specific operation or material)? What’s your current lead time? ”

Small shifts in tone go a long way toward building trust and respect.

7. Timing and Follow-Up Matter

Many factories are based in Asia or Europe, meaning your 10 a.m. Email may land after office hours. If you don’t hear back immediately, it doesn’t always mean “no.” It might just mean your message got buried.

Fix:

Follow up regularly, but respectfully. Some questions factories can answer immediately, like information on their own internal policies, processes, etc. But things like sourcing materials and trim do take longer, as a factory is having to contact other businesses to find all the correct items for your project. Keep your follow-up in line with the type of request, and keep messages short and friendly:

“Hi [Name], just checking if you had a chance to review my inquiry below. Would love to explore if we’re a good fit.”

Avoid spamming, but persistence—done politely—signals professionalism.

8. You’re Not a Good Fit (Yet)

Sometimes, the factory sees your product type, volume, or timeline and realizes it’s not aligned with their current setup. That’s okay; it’s not personal.

Fix:

Focus on finding the right-sized factory for your stage. Smaller, boutique manufacturers or sample studios are often better matches for emerging brands than large-scale operations.

The Bottom Line

If factories aren’t replying to your emails, it’s usually because they can’t see a clear win-win from the start.

By sending a detailed, professional inquiry complete with a tech pack, realistic quantities, and a collaborative tone, you’ll stand out from the crowd.

It’s not about chasing factories. It’s about attracting the right one by showing you’re ready to work smart.

Need help preparing your first tech pack? At Tech Packs Co, we help emerging fashion brands create professional, production-ready tech packs that get factory responses—and results. Book a free consultation to get started.

Author Bio

Tech Packs Co founder Belinda is a technical fashion designer from London, now based in Los Angeles. Belinda had her first job in fashion at the age of 15, fixing swatch cards together. Since then, Belinda has been designing & creating tech packs for more than a decade... for household name brands and independent designers alike.